Collaborative robot palletizers work closely with human workers to improve production efficiency and flexibly adapt to different tasks. Safety sensors are equipped to create a safer and more efficient working environment for workers. The appearance is exquisite and beautiful, and the adjustment is convenient and simple. This equipment uses a touch screen to achieve intelligent operation and management, which is simple and easy to master. It can greatly reduce the number of workers and reduce labor intensity. It can be used independently or in conjunction with automatic palletizers and pallet conveyors to realize a fully automatic palletizing system. It is widely used in the palletizing process of multiple industries, such as cartons, medicines, daily necessities, food, beverages, cosmetics, metal products, etc.

|

Palletizing Speed

|

15-20 boxes/minute (customizable for dual-box suction)

|

|

Payload

|

40KG

|

|

Working Radius

|

1700mm

|

|

Machine Height

|

1800mm-30000mm

|

|

Palletizing Height

|

1800mm-2400mm (including pallet height)

|

|

Arm Length

|

1700mm

|

|

Applicable Pallet Size

|

1200mm*1200mm*140mm

|

|

Footprint

|

6㎡ (including dual-stack)

|

|

Equipment Weight

|

550KG

|

|

Temperature Range

|

0-55°C

|

|

Rated Voltage

|

Single-phase 220V

|

|

Equipment Power

|

2500W-3300W

|

|

Protection Level

|

IP54

|

|

Repeat Positioning Accuracy

|

±5mm

|

|

Compatible Dimensions

|

Length: 120-600mm, Width: 80-600mm, Height: 120-600mm

|

|

Compatible Surface

|

Regular carton surface, various smooth surfaces, various metal surfaces

|

1.Intelligent collaboration:Self-developed kernel operating system, fast switching of multiple functional scenarios, achieving true human-machine collaboration, and secondary development.

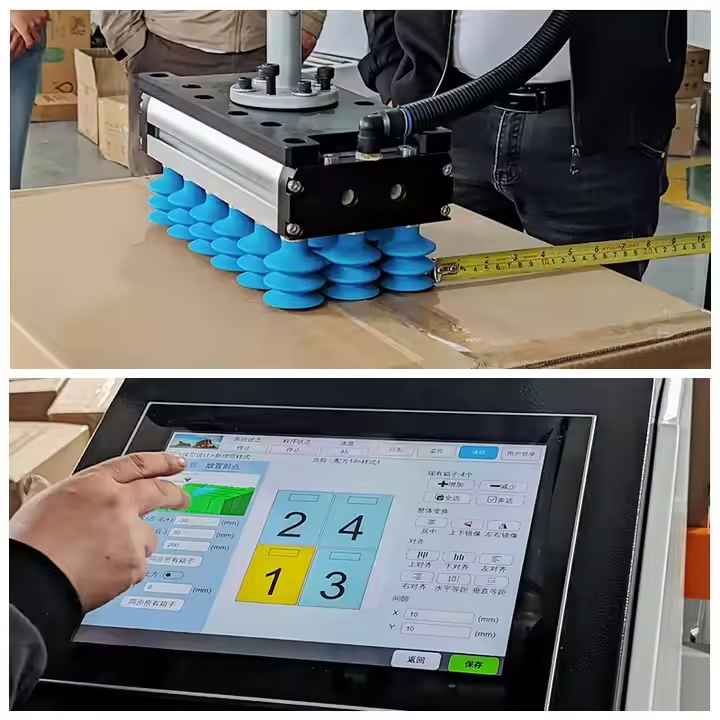

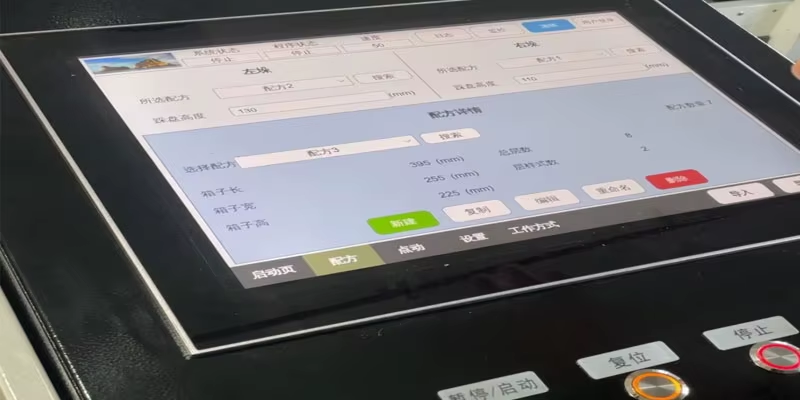

No Programming & Visual Operation15 inch highly sensitive capacitive touch screen, collaborative palletizer robot system, can generate palletizing solutions according to the guided input of box, pallet and other material dimensions, and no programming is required during the operation. |

|

|

Cost ControllableSelf-developed kernel operating system, no need for users to add additional sensor equipment, etc., the overall solution cost is controllable |

Visualization of StackingVisualized stomping helps operators better observe the effect and rationality of stomping, and facilitates real-time control and adjustment. Set a new path within 5 minutes. Support multi-language settings |

|

|

Low consumption & high configurationVisualized stomping helps operators better observe the effect and rationality of stomping, and facilitates real-time control and adjustment. Set a new path within 5 minutes. Support multi-language settings |

High Quality MaterialsMade of magnesium-aluminum alloy, it can adapt to complex production environments such as corrosion and oxidation; |

|

|

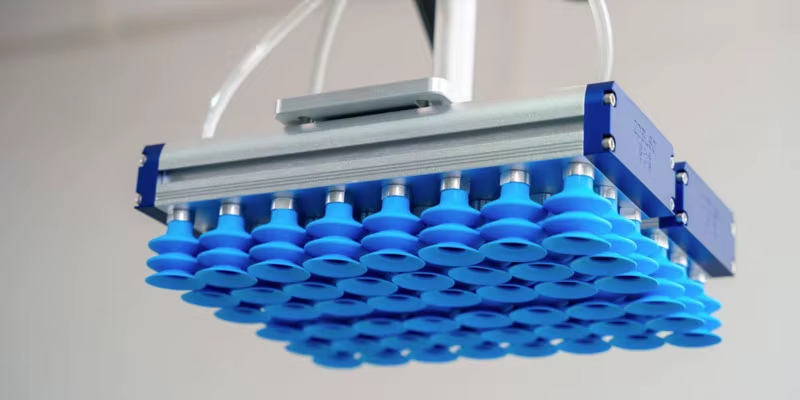

End EffectorSilicone vacuum suction cups are more durable, have a long service life, low maintenance costs, are economical, and are suitable for use on various surfaces. You can choose to connect to external devices such as fixtures and suction cups as needed, which is convenient to disassemble and replace. |

Easy to OperateMade of magnesium-aluminum alloy, it can adapt to complex production environments such as corrosion and oxidation; |

|

|

Easy to MoveWith the foot cup design, the manual trailer can be easily moved and can be moved at any time and used upstairs, making it more widely applicable and flexible. |

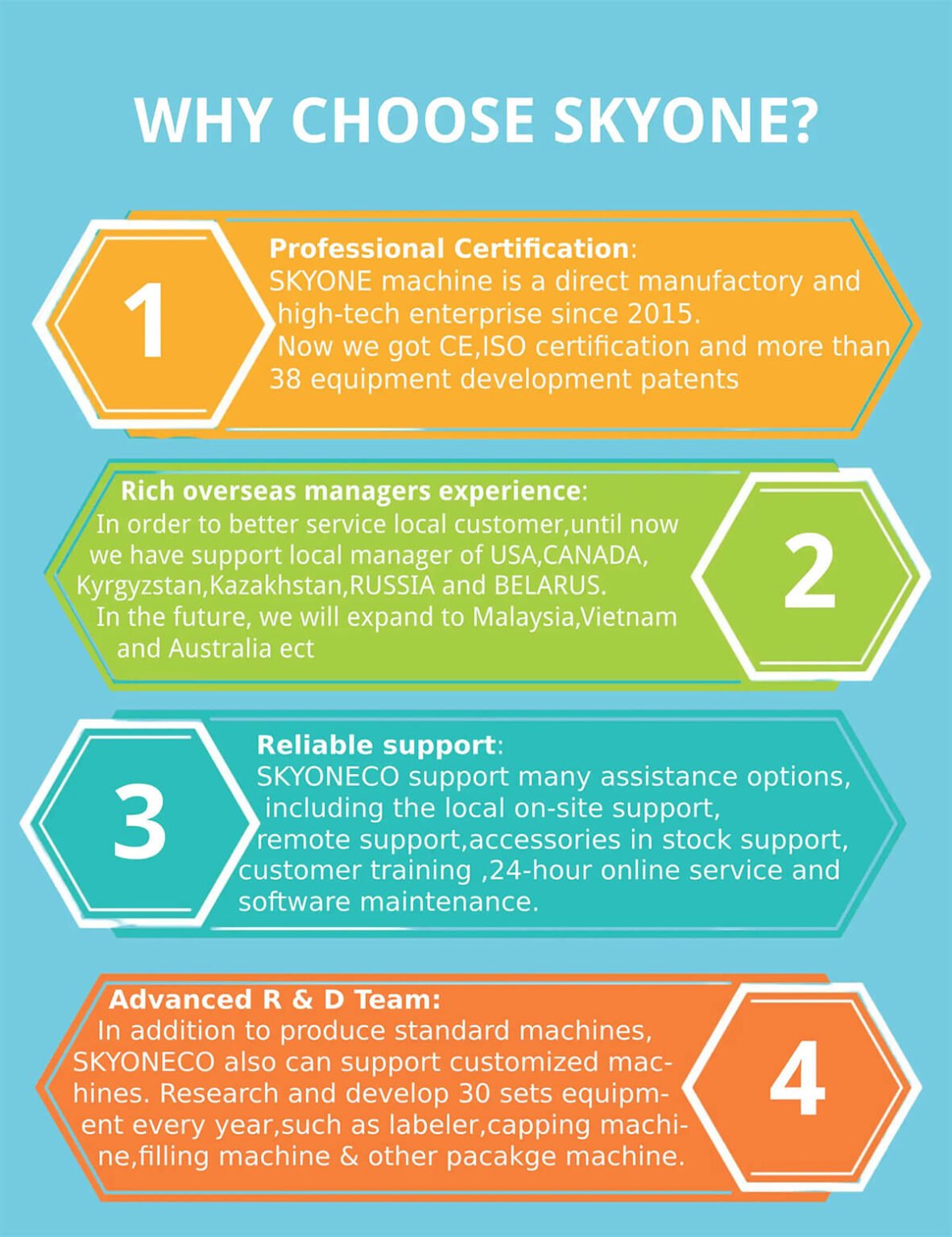

SKYONECO Machinery was established in 2015, which located in dongguan city,guangdong province.

SKYONECO have specialized in packing machine field more than 9 years. There are 60 employees including 30 experienced R & D engineers.SKYONECO have CE, ISO certification and more than 38 equipment development patents.

In 2019, SKYONECO applied for a high-tech enterprise successfully, will try our best to contribute to the development of the industrial field.

Q1.How much is the package machine?

A:Please send me your product pictures and label /product size,then we can check the best price for you.

Q2.What’s the lead time of machine?

A.It is 1-3 days

Q3.Does the machine HMI in English?

A.Yes,our labeling machine HMI is in English, we also provide other language like Spanish,Germany,French,Russian and Korean etc.

Q4.Is it easy to set up?

A.Yes,the design of package machine is very human.After receiving machine,no need to assemble,just power on,then install label rolls, and do some simple setting, then you can run it.

Q5.What’s the power of the machine?

A.Our standard machine power is 220V, if your local power is 110V or other, you need to buy a power adaptor for it. (We also provide adaptor)

Q6.Can i add the code printer or Zebra printer with SKYONE machine?

A.Yes,we can add the code printer function or Zebra printer with SKYONE machine,if you just want to print dates and numbers in your label,you can choose code printer,but if you want to print whole label or many contents in your label,you need to choose the printer,such as Zebra printer or other brand.

Thank you for your interest in our products and solutions. Please fill out the quick form and we will be in touch ASAP.

ADDRESS:

Office 1: Room 103, Unit 2, Building 9, UCC, No. 428,Nancheng Street, Dongguan City, Guangdong Province, China

Office 2: Room 103, Building 3, No. 8, Shangtun Southwest Road, Liaobu, Dongguan City, Guangdong Province, China

PHONE: +86 15578346096

EMAIL: info@skyonecomachine.com

Open Hours

If you have any questions on Packing Machinery or Industrial Intelligent Equipment, please feel free to Contact Us 24/7.We will reply within 24 hours.

STAY CONNECTED

Email

info@skyonecomachine.com

Phone/Whatsapp

+86 15578346096

Office 1: Room 1301, Unit 2, Building 9, UCC, No. 428,Nancheng Street, Dongguan City, Guangdong

Office 2: Room 103, Building 3, No. 8, Shangtun Southwest Road, Liaobu, Dongguan City, Guangdong Province

Thank you for your interest in our products and solutions. Please fill out the quick form and we will be in touch ASAP.